Every day, people interact with dozens of surfaces — door handles, desks, touchscreens, public transport handrails, and countless others. Many of these surfaces can accumulate microorganisms that persist for long periods of time, contributing to the spread of infections in hospitals, schools, offices, and public spaces.

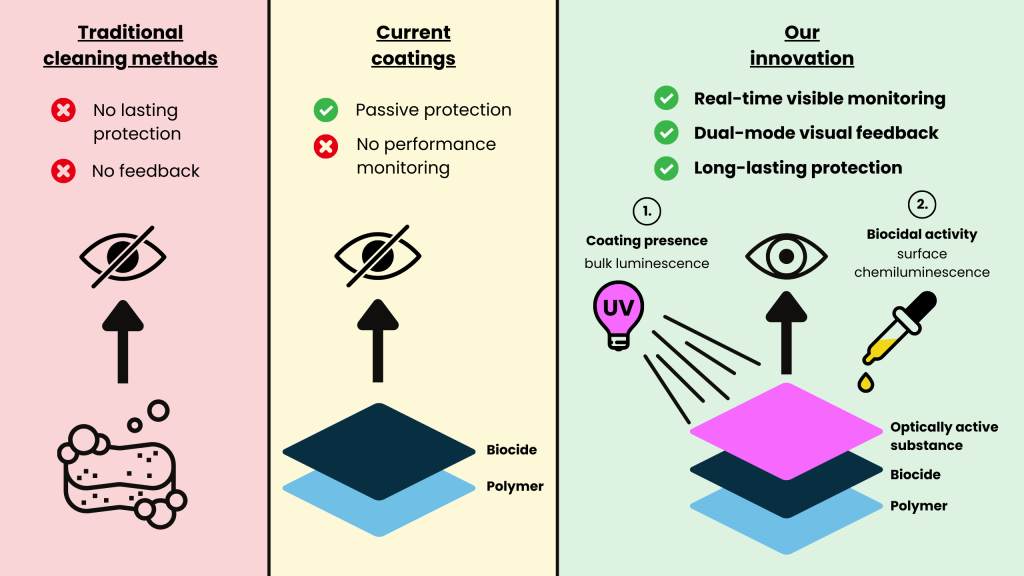

Current hygiene practices rely mainly on:

- intermittent, labour-intensive disinfection,

- short-term surface protection,

- fixed reapplication schedules,

- no real way to verify when the protective layer stops working.

This creates a critical visibility gap: surfaces may look clean, but there is no feedback mechanism that indicates whether the antimicrobial coating is still active.

Our Approach: A Smart, Optically Active Coating

We are developing a transparent, spray-applied antimicrobial coating that not only protects surfaces but can also signal its own presence and functional state.

This functionality is made possible by integrating optically responsive materials into the coating. These materials provide two independent but complementary capabilities:

- Verification of coating presence — the coating can be detected optically without affecting the surface’s everyday appearance.

- Indication of antimicrobial activity — the surface can generate a measurable optical signal correlated with its active protective state.

This concept represents a shift from traditional background protection to intelligent, self-reporting surface hygiene — an innovation currently missing in commercially available products.

Why This Matters

1. Improved Hygiene Management in High-Risk Environments

Hospitals, laboratories, educational institutions, food-service areas, and public transport systems benefit from continuous hygiene assurance. A coating capable of reporting its activity provides a more reliable barrier against microbial contamination.

2. Evidence-Based and Resource-Efficient Maintenance

By understanding when a coating is still active, users can move from routine reapplication to condition-based maintenance:

- fewer unnecessary chemical treatments,

- optimized labour and time,

- reduced material consumption and environmental impact.

3. Increased Transparency and Trust

Cleanliness is typically invisible. An optically responsive surface creates a verifiable, data-driven hygiene standard, allowing users, facility managers, and the public to trust what they cannot see.

A Scientifically Grounded Development Strategy

Our work brings together materials science, optical spectroscopy, polymer chemistry, and microbiology. The aim is to create a durable, user-friendly coating that meets high scientific and regulatory standards.

Key principles of the development include:

- the use of environmentally compatible materials,

- stable optically active components that do not alter surface appearance,

- long-term durability under routine cleaning and environmental exposure,

- safe and scalable formulation suitable for real-world deployment.

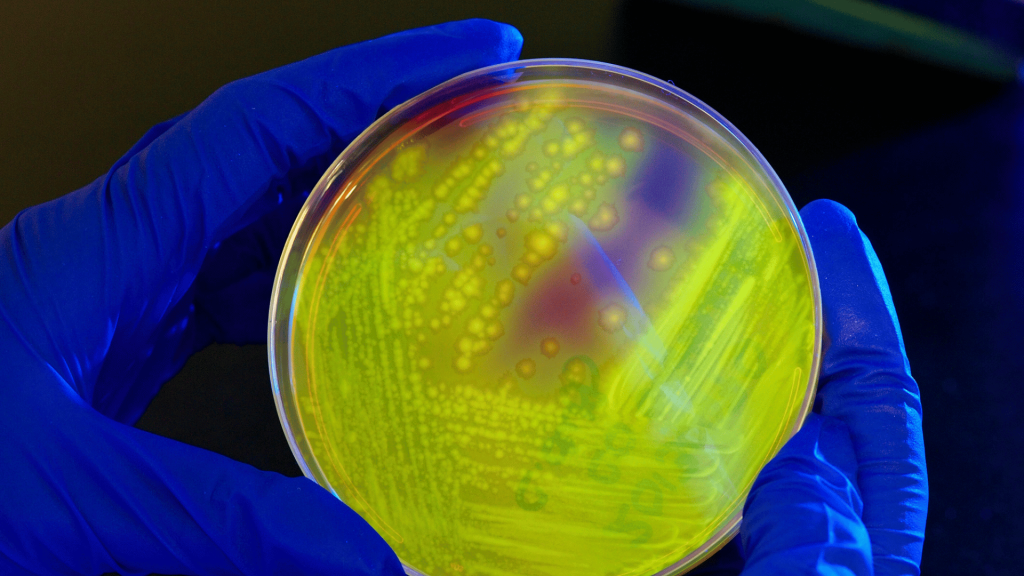

The correlation between optical responses and antimicrobial activity is a central research direction, enabling the transition toward a functional prototype that supports real-time, non-invasive monitoring.

Our Vision for the Future of Surface Hygiene

We envision a future where surfaces are not only protected but also capable of providing direct feedback on their hygienic status. Such intelligent materials can contribute to safer public environments, more efficient maintenance strategies, and greater confidence in hygiene standards.

Our goal is to make this next-generation technology practical, accessible, and impactful — from healthcare and industry to everyday public spaces.